Mit-ivy industrija metalni napredni akrilni lateksni brtveni premaz s izvrsnom probojnom snagom

primjena

Ima izvrsno prianjanje na čelične podloge i slične podloge na vodenoj bazi te izvrsna fizikalna i mehanička svojstva nakon što se val boje osuši.

5. Film za bojanje ima izvrsno očuvanje svjetlosti i očuvanje boje nakon sušenja.

Preporučena primjena Pogodna je za zaštitu od drenaže kamiona, dijelova strojeva, lagane industrijske opreme itd. Gdje je potrebna visoka zaštita.

Tehnički podaci Odabir boje

Suha površina (50% mješljivosti) 15 ℃ C <1h ; 25'C <0,5h

Čvrsto suho (50% vlage) 15'C <48h; 25 ° C <24 h

Pogoci "kg.cm" 50

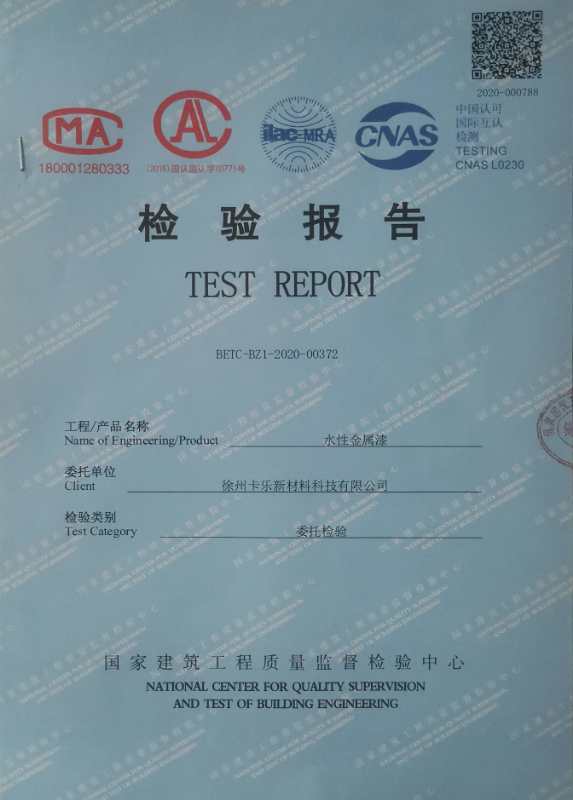

Voda (50 ± 5μm) 72h film za boju ne stvara mjehuriće, ne pomaže padu, ne hrđa.

Tvrdoća 0,3 (dvostruko klatno) ispitivanje mehaničkih svojstava debljina filma (23 ± 3jμm)

Adhezija (hegelovska) Razina 1

Obrada površine Površina presvučenog materijala ne smije sadržavati vlagu, ulje, kiseli ugljik i pepeo.

Brzi detalji

Čelik s oksidnom kožom: Metode pjeskarenja ili pjeskarenja poput obrade do razine Sa2,5, gdje se pjeskarenje ne može izvršiti, trebaju se mehanički polirati ili

Kemijski tretiran da ukloni sva plutajuća slomljena ramena.

Čelik bez oksidne kože: pjeskareni (pjeskareni) do Sa2.5 ili zračno aktivirani, električni alati za brušenje do St3.

Zavarivanje, rezanje plamenom ili korekcija vatrometa izgorjelih područja luka: brušenje do razine St3.

Osnovni materijal sa starim filmom boje: uklonite rastresite stare čestice boje i hrđu te brusite St3 zrakom ili električnim alatima za brušenje.

Tipični paket za bojanje može se upotrijebiti s temeljnim premazom na bazi vode H902, ili samostalno kao općeniti ukrasni završni premaz, ili s drugim vrstama proizvoda za temeljne boje (potrebno ih je uskladiti radi provjere).

Construction data Table dry (50% temperature) 15'C<th;25℃C<05h Actual dry (50% humidity) 15℃C<24h;25℃<12h Density about 1.1-1.20g/cm' Theoretical coating rate 0.15-0.2kg/m' (dry film 40-50) μm)

It is recommended to apply 2 coatings, which can be applied in the way of warm touching temperature to ensure that the dry film is 40-50μm.

To be sanded and finished with sandpaper.

Construction method Air or robot spraying is possible. Mix the paint before use, adjust the viscosity according to the construction method.

Add 5-15% of water. Add water and stir evenly, then leave the surface to work without bubbles.

Construction environment 1. The brain playground should have good ventilation and dust removal facilities to ensure the quality of construction.

2. The construction should be carried out under the condition that the mixing degree is above 5℃C and the relative humidity of the environment should be <70%.

3. The substrate temperature shall be not less than 5' and shall be more than 3'C above the air dew point temperature.

washout

| Vehicle Type | 100% Acrylic Latex | |

| COMPOSITION (nominal) | Pigment : Lightfast Non-Lead Pigments & Mineral Extenders.

Blinder : Acrylic Emulsion. Solvent : Water. |

|

| Volume Solids | 31.8% | |

| Coverage per Gallon at Recommended Film Thickness | 400 –450 Sq. Ft. (37-42 m2) | |

| Recommended Film Thickness

(Depending on surface texture and porosity. Be sure to estimate the right amount of paint for the job. This will ensure color uniformity and minimize the disposal of excess paint) |

Dry 1.2 mils

Wet 3.8 mils |

|

| Dry Time @ 77° F (25° C) @ 50% RH

(High humidity and cool temperatures will result in longer dry, recoat and service times.) |

To Touch 1 Hour

To Recoat 2 to 4 Hours |

|

| Dries By | Evaporation, Coalescence | |

| Viscosity | 99 ± 2 KU | |

| Gloss / Sheen | Flat (5-10 @ 85°) |

| Shipping time by Sea (Just for reference) | ||||||||

|

North America |

11~30 days | North Africa | 20~40 days | Europe | 22~45 days | South-east Asia | 7~10 days | |

| South America | 25~35 days | WestAfrica | 30~60 days | MiddleEast | 15~30 days | East Asia | 2~3 days | |

| Middle America | 20~35 days | EestAfrica | 23~30 days | Ocenia | 15~20 days | South Asia | 10~25 days | |

FAQ

1.About Sample

We provide free sample for testing.

2.OEM,ODM service available.

3.According to customer's request, packed with pallet or without pallet.

Tile adhesive(20kg/bag)packing with pallet specification:

64 bags/pallet = 1.28 MT/pallet

72 bags/pallet = 1.44 MT/pallet

One full 20ft container max loading 27.6MT.

With pallets can load 1360 bags, without pallet can load 1380 bags.